Nickel Hypophoshite

Product Details:

- Structural Formula Fe(H2PO2)3

- HS Code 28351090

- Molecular Weight 292.73 g/mol Grams (g)

- Solubility Very Soluble in water

- Ph Level 3.0 to 5.5

- Color Other

- Click to view more

Nickel Hypophoshite Price And Quantity

- 100 Kilograms

Nickel Hypophoshite Product Specifications

- 292.73 g/mol Grams (g)

- 3.0 to 5.5

- Other

- 28351090

- Fe(H2PO2)3

- Very Soluble in water

Nickel Hypophoshite Trade Information

- Cash Advance (CA)

- No

- Free samples are available

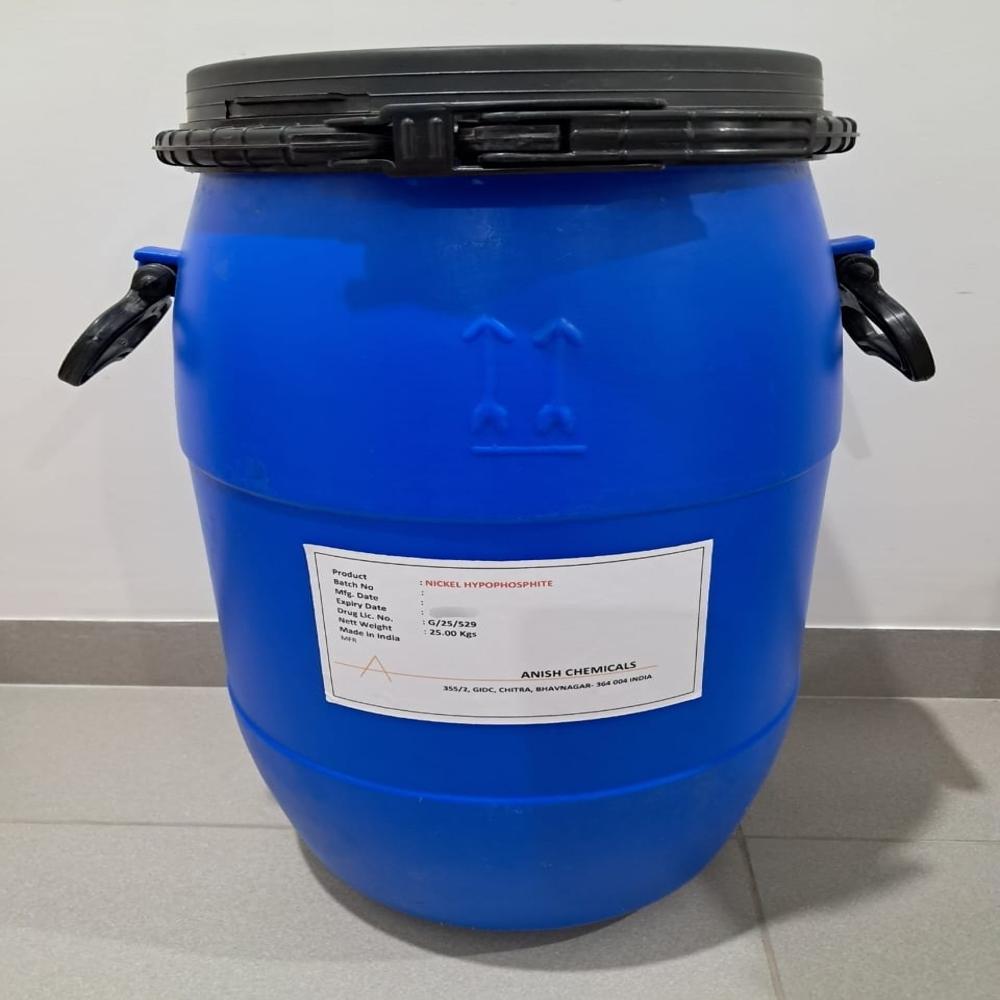

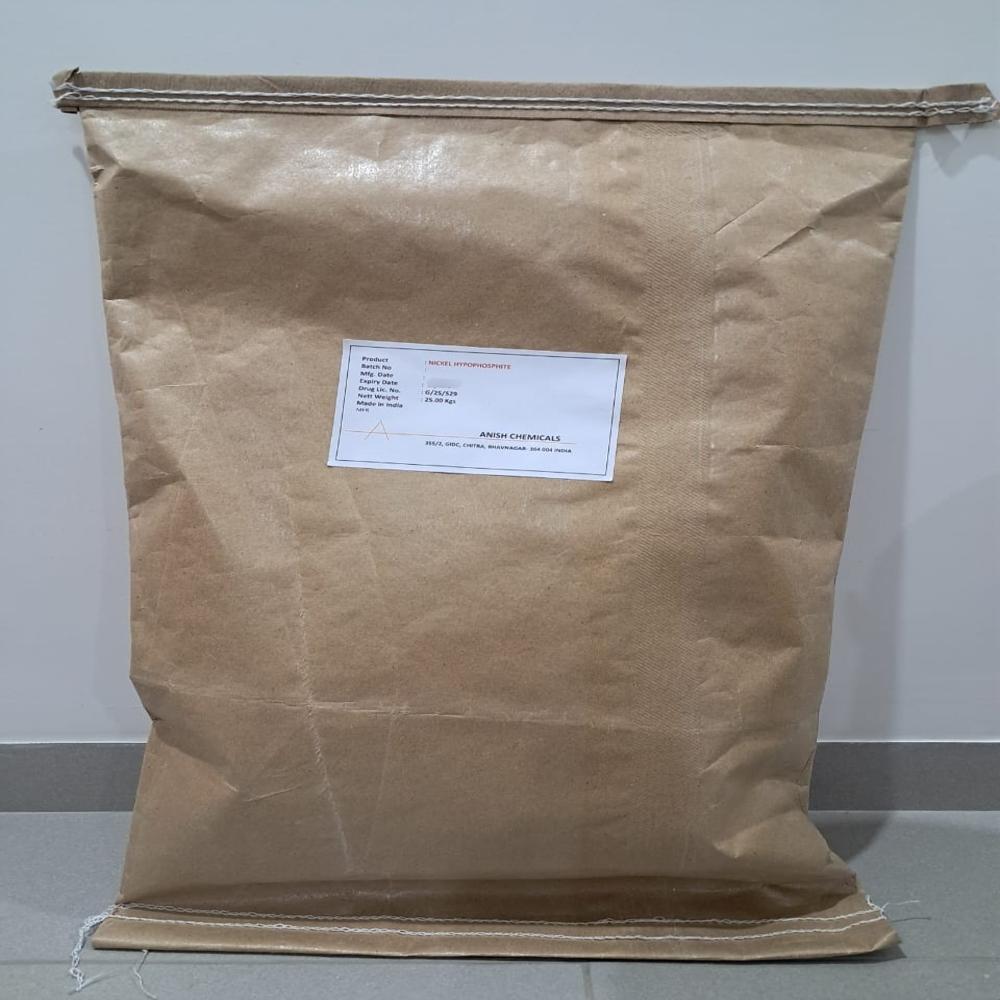

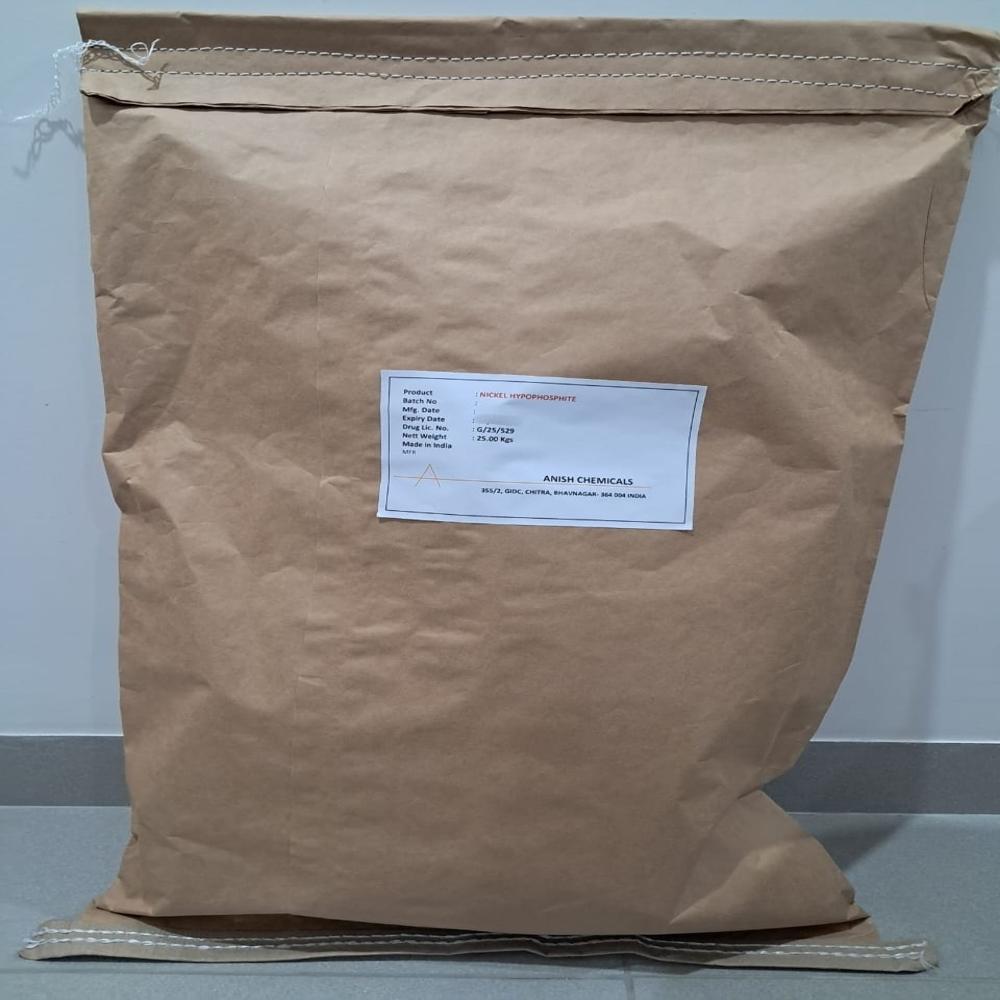

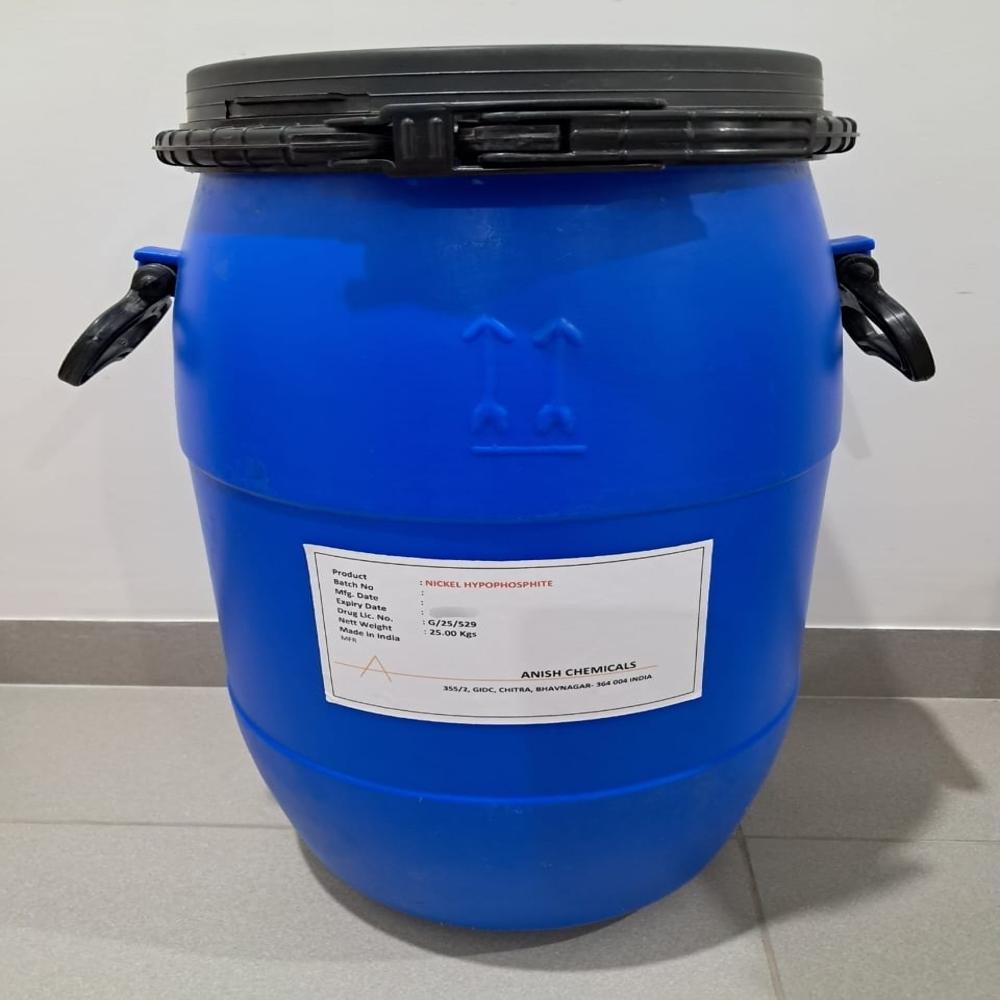

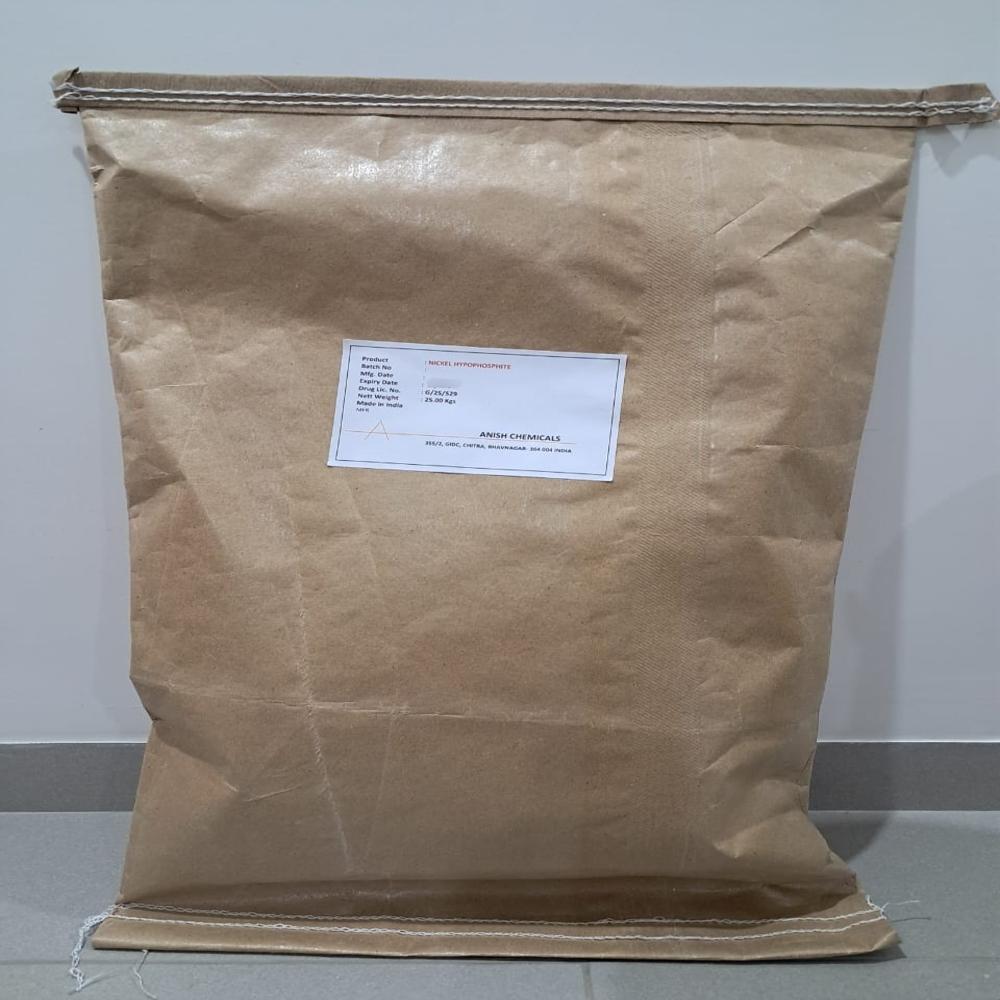

- 25 KG - HDPE Woven bags with inner liner LDPE Liner 25 KG - HDPE Drum with inner liner LDPE Liner 50 KG - HDPE Drum with inner liner LDPE Liner 25 KG - Kraft Paper Drum with inner LDPE Liner 50 KG - Kraft Paper Drum with inner LDPE Liner 25 KG - 3 Ply Paper bag with inner LDPE Liner 25 KG - Kraft Paper laminated HDPE Bag with Liner LDPE Liner

- All India

- Production certified according to Local GMP, FSSC22000, ISO 9001:2015, Halal & Kosher

Product Description

Applications/Uses

Coating Food Processing Equipment: Electroless nickel plating, which utilizes hypophosphites (usually sodium hypophosphite) as the reducing agent, is applied to components such as molds, grills, freezers, mixing bowls, blades, and pneumatic canning machines.

Benefits of the Coating: This coating improves wear resistance, hardness, and corrosion resistance, which is vital in the demanding and often acidic or alkaline environments of food production facilities, and can be used to replace stainless steel materials in certain applications.

Coating Pharmaceutical Machinery: The durable finish is applied to intricate parts and components such as capsule machinery dies, pill sorters, and feed screws, where high wear resistance and specific tolerances are required.

Protection of Equipment: The coating helps protect components from corrosion and wear, extending their lifespan and ensuring hygiene standards are met.

Dietary Information: The product is suitable for the following nutrition: Kosher, Halal, Vegetarian, Vegan

Allergen Free, GMO Free, Irradiation Free

Specifications

|

Grade |

IHS |

|

Description |

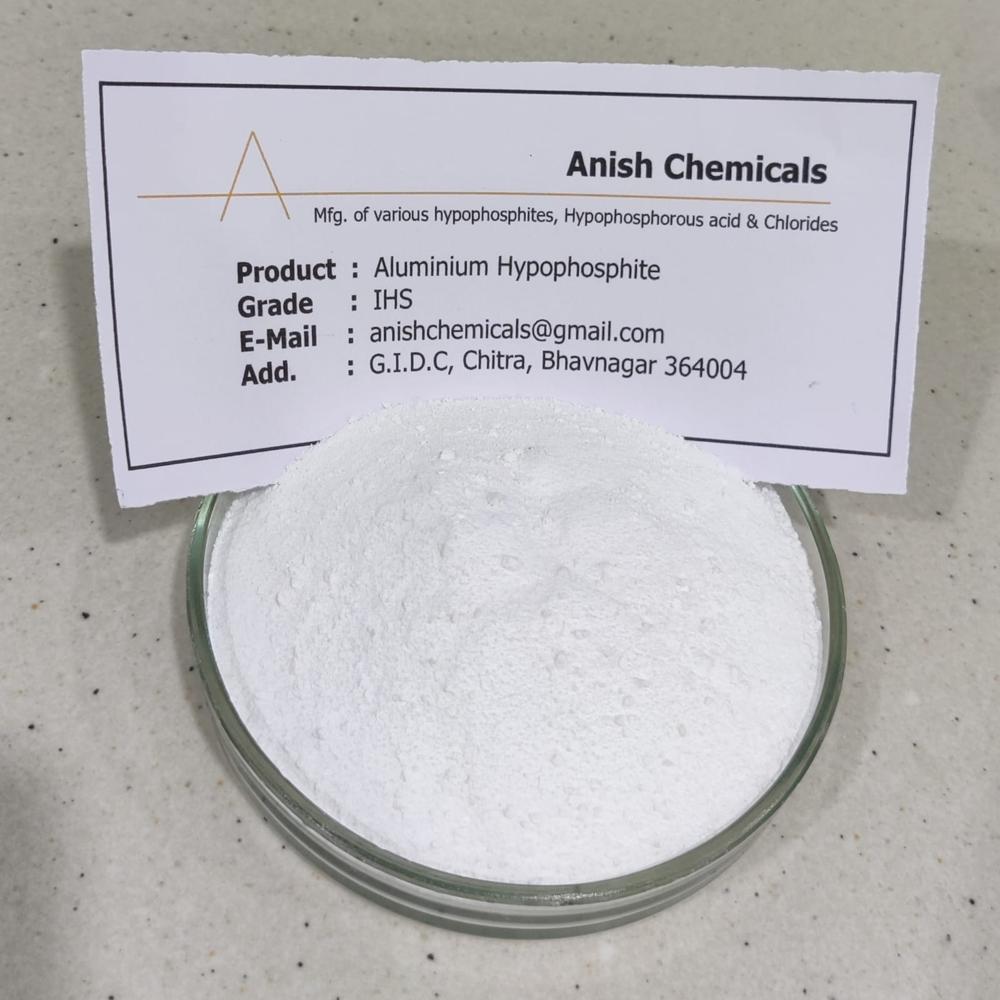

A White or greyish white powder, Odourless, tasteless. |

|

Identification |

Should give characteristic reactions for Ammonium salts and Hypophosphite salts |

|

Solubility |

2.0 gms soluble in 10.0 ml distilled water |

|

Sulphate |

Not more than 0.05% |

|

Iron |

Not More than 10 ppm |

|

Chloride |

Not more than 300 ppm |

|

Calcium |

Nil |

|

Barium |

Nil |

|

Phosphite |

Not more than 0.05% |

|

Arsenic |

Not more than 2 ppm |

|

Lead |

Not more than 5 ppm |

|

Loss on Drying |

Not More than 5 % at 105oC |

|

Assay |

97.0 % to 102.0 % |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+